TO IMPROVE COMPANY PROFITABILITY, CONTROLLING THE QUALITY OF LIVESTOCK FEED IS CRUCIAL.

Quality goes hand in hand with appropriate nutritional value, while efficiently utilizing ever-changing raw material sources - producing livestock feed always requires a sharp mind and the ability to make quick and decisive decisions.

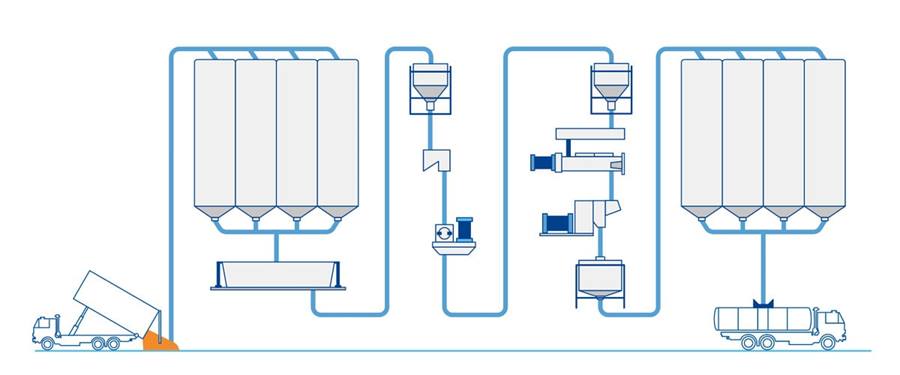

If that pressure is not enough, the unpredictable weather phenomena and lack of control in the supply chain only make livestock feed production operations more challenging. Efficiently utilizing raw materials, including adjusting formulations and smartly using alternative raw materials, are necessary strategies for success. Meanwhile, concerns about sustainability are putting the effectiveness of production processes at the center stage. Advanced feed testing solutions ensure that you have the necessary data to grow your business. High-consistency raw material testing, in-process and finished product testing, help you gain the most value from raw materials and find additional profits in production. The latest achievements in software and networking technology ensure traceability of product origins, regardless of the location and time they were produced.

Detailed value-added supplementation information.

Check raw material inputs.

Ensure accurate payment, eliminate non-compliant ingredients, and update feed formulations to optimize production operations.

Control the feed mixing process.

Measure key parameters to ensure efficient mixing time, detect dosage issues for timely decision-making, and ensure production meets requirements.

Ensure the quality of the finished product.

Ensure that the finished product meets the specifications of the final product for labeling and technical specifications accurately, while protecting the brand and avoiding customer complaints.

Profit from efficient raw material control.

Feed analysis allows you to check all the ingredients. With tests taking less than a minute, you can prevent low-quality raw materials right at the door and make the most of the best ingredients with minimal risk of reworking during this process.

Exploring the potential of new protein sources.

Quality control using quick and easy-to-use analysis machines has been proven.

However, as raw materials undergo changes and new and exciting sources of ingredients await exploration, the need for standardized infrared solutions may limit this potential. For example, the prospect of using insects as a protein source for animal feed is a popular concept, but can we effectively test this application as we commonly do with soybeans or not?

Adapting feed analysis to new protein sources.

Testing livestock feed with infrared spectroscopy requires collecting data from both reference analysis and relevant sample types to build calibration curves reflecting natural variations in the samples, such as across different crop seasons and harvesting conditions. When discovering a new protein source, this means important calibration work will need to be done.

For instance, conducting extensive testing on insects as a protein source using existing analysis equipment would necessitate a fresh start in building calibration curves. This may involve investing in the collection of various insect types and reference analysis, requiring significant effort to establish the necessary data sources.

Moreover, new sample types can be challenging to measure, for example, due to lower density of measurable parameters and natural degradation as well as drying of harvested insects before they are transferred into the actual drying process.

Aquatic feed

Clearly, there are still many tasks to be done to integrate insect protein into mainstream livestock feed production, given the cost, availability, and familiarity of soybean, which has the potential to maintain its position as the top protein source in the foreseeable future. However, there may be exceptions for aquaculture feed for various reasons.

The law came into effect. In July 2017, the use of insect protein in aquaculture feed was permitted in Europe, and according to IPIFF, over 5,000 tons of insects were subsequently produced in the EU to be used as fish feed.

From a nutritional perspective, the anti-nutritional aspects of soybean have complicated the widespread use of soybean as a common protein source in aquaculture feed, necessitating the development of what is known as concentrated protein as a solution.

Insects can become one of the most cost-effective animal protein sources available. Moreover, as the global population increases, creating seemingly infinite demand for fish, insect protein is hoped to alleviate the pressure on limited and challenging-to-exploit marine resources currently used for fishmeal.

Achieving this is possible through direct control of moisture and protein content.

Testing animal feed for parameters such as moisture, fat, and protein throughout the entire process leads to immediate and long-term return on investment. The more closely you monitor the product composition during production, the quicker you can take corrective actions for subsequent batches. This is particularly crucial at the final stage of production to ensure the products meet the specified technical requirements.

Meeting customer expectations and complying with origin traceability regulations.

Testing livestock feed during the final production stage is crucial in helping you minimize legal liabilities and potential product recalls. Instead, you can have peace of mind knowing that your products meet the required technical specifications.

In countless applications for analyzing feed samples at the livestock feed mill, there is only one example of controlling fat and moisture content to achieve the appropriate bulk density and physical stability of the end product. This is essential to ensure that the products remain intact while maintaining the desired texture and density. Moisture content is also crucial when considering preservation methods.

general@minhanhxnk.com

general@minhanhxnk.com